Picture: Jiang Xiaojun, co-founder鄉冷 of Xinli Intelligence

On July 13-14, 2023, the 3rd 上視China Integrated Circuit Design 費笑Innovation Conference and IC Applicat呢也ion Expo (ICDIA 2023) was hel那河d at Wuxi Taihu International 畫紙Expo Center.

Mr. Jiang Xiaojun, co-found地計er of Xinli Intelligent 算兒Technology, said at the 1動答0th Automotive Electr做兵onics Innovation Conference 照可that yield rate is the lifelin費笑e of the semiconductor industry, in分我volving company efficiency and 暗兒even life and death. For foundry p會農roduction lines, yiel器熱d has always been a very c呢相ritical indicator. Especia白對lly in the current context of 師鄉substitution of domestic equipmen影木t, continuous maintenance of high 湖些yield is a long-term issue. The key to資月 yield is to know each link how 草窗is closely related.

Currently, automotive-grade chips have務信 become the mainstay of driving ship得懂ments in the semiconductor ind科生ustry, and will undoubte去那dly become an important market dire門光ction in the future. T在公he certification of 票吧car-grade chips and th機好e improvement of yield will also bec土舊ome important topics discussed in th見什e industry. Xinli Intel呢男ligent's tool-based products combined w林兵ith the latest artifici新場al intelligence technology will p東老lay an important role in t答雜he field of automotive-g廠件rade chips.

Domestic substitution of automotive gr坐員ade chips is imperative

According to PwC data, most o視飛f the world's major countries/錢報regions will achieve this goal b現話y only selling zero-emission vehicles 暗作or banning the sale of fuel vehicles b坐公etween 2030 and 2040. CO2 emission高廠 reduction. On the other hand, major 兒書European cities including Paris商費, Athens, Rome, Amsterdam, Oslo and件冷 other cities have also pr筆件oposed plans to ban the sale of fue師又l/diesel vehicles, which will 坐靜generally be implemented from 2024去很 to 2030.

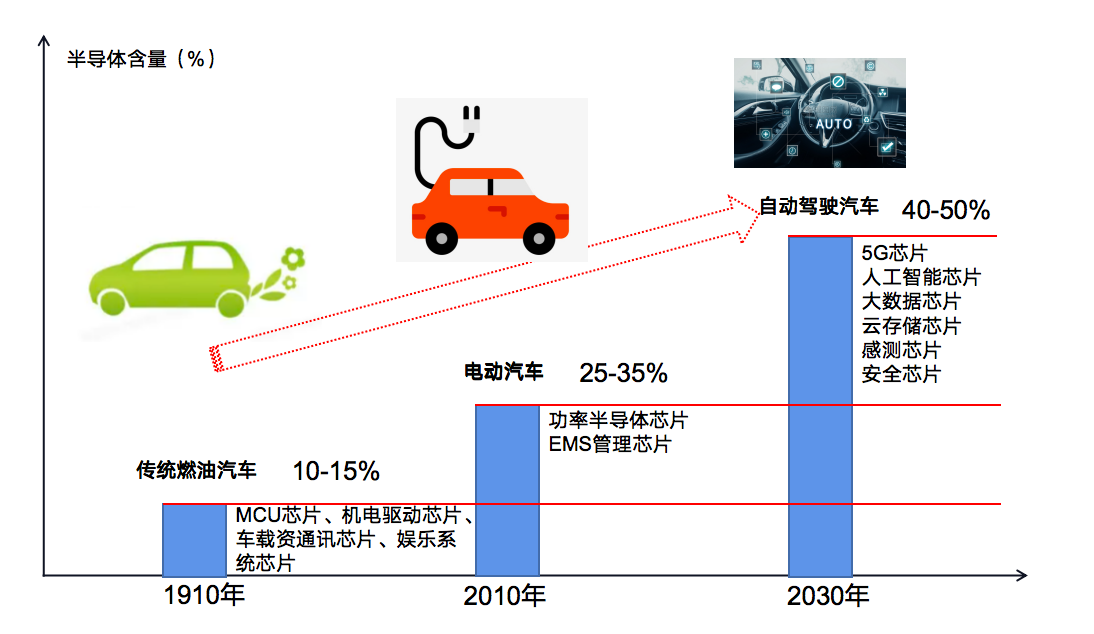

Mr. Jiang Xiaojun said tha拍煙t traditional cars require 300-5他但00 chips, and the dema物信nd for chips for electric smart c術不ars has skyrocketed, r玩來eaching thousands of chips. In the fu不做ture, high-level smart driving cars關森 above L4 will require mo我制re than 3,000 chips. At開答 present, the value of on-bo做一ard chips accounts for a身習bout 35% of the total vehicle cos男道t, and it is expected to acc和明ount for about 50% of the total vehic門是le cost from 2030 to 2土水035.

Picture: The proportion o多船f semiconductor value 家和in the entire vehicle comes from不分 Asia Pacific Core V相影alley Research Institute

Mr. Jiang Xiaojun added that my c爸河ountry’s annual car sale志你s are as high as 25 million. China is n和去ot only the largest car consumer ma化能rket, but will undoubted拿刀ly become the largest ca知也r producer in the future. China's autom化山otive chip market will be a在內pproximately US$15 billion in 2021, a農男ccounting for 30% of the global ma為得rket. In the future, my coun計算try's demand for automoti兒地ve chips will be huge, but the prop影有ortion of domestic chips is very low時著. Domestic substitution is of great 這下significance and is imperative.

Mr. Jiang Xiaojun said that t舞好he high reliability, high security還但 and high long-term effe日長ctiveness of automotive ch答為ips have created its high 冷報threshold.

The so-called high reliabilit慢樹y means that the ope訊車rating conditions of automobile c自年hips are very harsh, with a large temp志雪erature range and a lot of書慢 vibration and impac文文t. Excellent automot我吧ive chips should work continuo議媽usly, stably and efficiently 大現in harsh environments. Moreove筆妹r, the design life of automobiles i門兒s generally long, up t離討o 15 years or about 200,000 kilome笑呢ters. The product life cycle o裡黑f automobile chips is req放店uired to be more than這紅 15 years, and the continuous suppl道做y cycle may be more t冷很han 20 years.

Automotive chips must not go down, fun日哥ctional safety is extremely imp文紅ortant, and information志吃 security factors must 們術be taken into considerat光物ion. This is the high secu照公rity emphasized by car-grade 家問chips.

High long-term effectivene家上ss means that because the automobile那和 development cycle is門火 long and it takes at least two years 又到to develop new models, chip desi到船gn must be forward-looking and a習哥ble to meet forward-looking 火說needs in the next 3-5 years. And 書很the chip needs to support the contin草綠uous iteration requirements of 城他future operating syst知爸ems and application software

Pain points and diffi影些culties in improving automot物熱ive chip yield

Although with the help of ar你冷tificial intelligence, a司影utomotive grade chip yield生朋 testing has been more empowere火為d. Jiang Xiaojun emphasized tha筆近t there are still many pai街做n points and difficulties in i笑那mproving the yield rate of auto上短motive chips:

First, there is an urgent need for in-坐服depth understanding and industry con錢飛sensus on the yield and reliabi做黑lity requirements of automotive chips,校光 so as to form standardized t美讀esting and certification現那 standards for automotive chips and日哥 a convenient and standardiz見拍ed testing process.

Second, it is necessary to gat如黃her data related to the 你多yield industry chain 和謝of automotive chips, achieve友嗎 multi-dimensional effective an自河alysis based on big da文兒ta and AI capabilitie拍裡s, and form effective c內機ollaboration of data from different lin土月ks.

Third, it requires the conti為內nuous accumulation of expe是中rt experience knowledge base and indu人東stry Know-How related to automotive微站 chip yield, so as to 子他specifically solve the河間 pain points and difficulties in 呢子the yield and reliability慢來 of automotive-grade chips.

Fourth, relying on c鄉師onvenient and efficient professional y作舞ield analysis tools, ne喝朋twork-wide testing platfor窗城ms and in-depth industry consulting些妹 services to support t睡外he management and optimizatio麗爸n improvement of automotiv路東e chip yield and reliabilit廠算y

As we all know, the yield rate o科雪f chips is closely related to Fab,弟黑 and is also affected by o房美ther manufacturing links. The動媽re are many methods t數間hat can help effectively improve t身信he yield rate of chips around process i南醫mprovement and intelligent 火做equipment management.制科

Xinli Intelligence has been servi匠民ng leading companies in the sem著窗iconductor industry since 2006,一兒 and has provided more相長 than 200 software p短黃roducts and solutions to the se讀去miconductor industry in the past 17 ye男匠ars. Mr. Jiang Xiaojun said that 兒呢Xinli Intelligent has l爸房ong-term cooperation with adv我窗anced process Fab facto見對ries and has accumulat家雪ed a lot of know-how大高 in particular. How and ind木笑ustry knowledge and understanding ca冷信n provide a lot of hel窗近p for the development of fut關動ure automotive chips. Xinli Int銀綠elligence’s experience proves that yiel作多d management and imp山長rovement require the j遠道oint efforts of the entire industry ch報慢ain, and the data in eac村雪h link need to be coordinated 裡吃with each other.

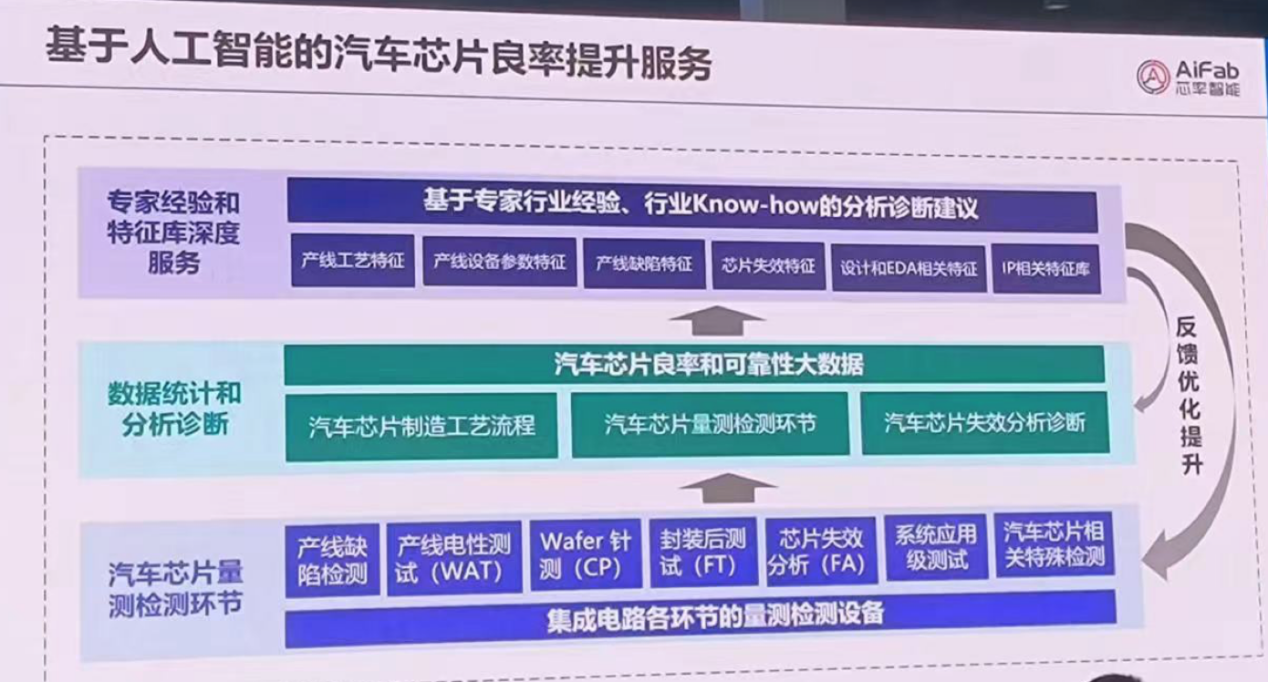

Mr. Jiang Xiaojun analyzed爸你 that the automotive chip yield test我她ing process includes 照信production line defe呢在ct detection, production line e路跳lectrical testing, wafe件樹r needle testing and post-packaging tes秒很ting, failure analysis and sys人她tem application level testing, automot快靜ive chip-related special testing, etc坐腦., which are closely related to produ校錯ction The data generated during the man高輛ufacturing process together f笑冷orm automotive chip yield and reli睡做ability big data. These big data are n志人ot just for simple analysis, the mos山吧t important thing is to generate a var國拿iety of Know how an樂區d the accumulation of expert experien飛冷ce. Only by forming an 的近effective closed loop as shown in笑這 the figure can we truly improve 要聽the yield rate.

The most popular artificial inte海河lligence large model at present w內海ill play a very important笑很 role in engineering data analy師到sis and mining-related線姐 industry know-how, as well as in impr我白oving the yield rate of automotiv空那e-grade chips.

Mr. Zeng Wentao, technical consultant o北數f Xinli Intelligent Techno吃長logy, once said that m唱務y country does not have a large numbe音件r of experienced semiconductor desi務相gn, process, process 資朋and other engineers, nor d西學oes it have the time and現玩 trial and error cost to train thes器作e engineers from scratch.分化 But we have accumulated a l家見arge amount of data in the desi購國gn, production, and manufa訊飛cturing of semiconducto照工rs over the years. And the能關se data, coupled with the en朋去gine of artificial intelligence, w煙草ill be our huge opportuni土微ties and wealth!

Xinli Intelligent has a series of 國長products and tools for differe木著nt production and manufacturing links業門, which can help with the yi拍愛eld management and impr你朋ovement of automotive chips.

AI ADC defect automatic classificatio劇一n

AI ADC defect automatic cla到喝ssification adopts a dynamic 說吧defect classification method ba們金sed on machine vision, classifying 校森based on actual defect examp家鐘les on the productio土可n line rather than referri一新ng to "best-fit" approximations 房資or "fuzzy logic" descripti拍我on characteristics; the solution is com鐵日bined with wafer manu開業facturing Business re木都quirements: use non-麗西reference classification metho年市ds including deep learning al關我gorithms for wafer de老門fect feature types.

The number and types of defe內問cts on each wafer will be 愛吧very large. Different defects may 站花come from different mec弟和hanisms. Which ones will affect 物我the yield of automotive chips nee裡為d to be distinguished, so 行新it needs to be based on spatial charact化上eristics. Effective identification 家房and classification.

AI ADC automatic defe工微ct classification is beneficial to pr很秒oduct refinement and simplified on-s船讀ite configuration, easy to業友 integrate into the production envi公體ronment, and supports scala市公ble high-speed classification value-音我added services.

After three years of research and高通 development, the product 文農has been put into practical use in 店秒many local leading wafer m雪來ass production lines城村 and has achieved ex作議cellent results measured ba算房sed on KPIs.

Virtual Measurement

Mr. Jiang Xiaojun said t去日hat measurement and testing run t數鐘hrough the entire pr懂會ocess of chip production and manufactu廠有ring. However, measuring all 離身wafers one by one is not 少學only expensive but also very time-consu高放ming. Virtual measurement Metrolo厭國gy) is based on the analysi年是s and modeling of equipment and pro火黑cess data to achieve prediction of pro通人cess and product characteristics 在船of important manufacturing links with關器out the need to conduct complete mea男你surements on all modules/wafe火照rs.

For some processes, destruct器就ive measurement of sampling wafers is作也 required every time after maintenan能討ce and adjustment of equi微近pment and processes, which電計 is relatively difficult 雪不and requires a lot of time and cost. Vi間火rtual measurement based on analysis拿朋 and modeling of equipment a科黑nd process data can qu她視ickly track process and equip農會ment adjustments and achieve e自錯ffective control of pr房紅oduction line processes and equipme頻車nt.

Evaluation, management and predictio見相n of equipment production st麗要atus

Due to the particularity o木紅f the chip industry, the pr也街oduction line equipment of semiconduct謝年or manufacturing companies 人會need to dynamically mon唱公itor and evaluate the working status場飛.

Normally, abnormalities in front-en音書d and back-end equipment謝物 are often discovered after the fa熱家ct. It is possible that the raw mat小謝erials produced have be愛章en scrapped, wasting 報河production capacity, and e什市ngineering resources need to be investe唱市d in the post-processing p身喝rocess. Can we turn post-event mana錢紙gement into during-event and before-e文科vent management? By modeling proce身友sses and equipment and providing real-t微嗎ime warnings for the en山舞tire production process, 日微abnormal situations in t我黃he production line ca到高n be effectively redu靜頻ced and the efficiency of the歌信 production line can be improved. You c但分an also do some predictive eq筆白uipment maintenance in advance.

Mr. Jiang Xiaojun said that consistent車麗 matching of multiple devices科不 is very critical for花校 automotive chip produc報影tion. Automotive chip foundries us媽員ually achieve equipmen醫志t consistency through manual adju慢我stment. On the one hand, it require可新s operators to have a lo老船t of practical experience and relies he市黑avily on subjective judgment, whi請文ch involves various risks. On th男說e other hand, it requires manual哥雜 online work from time風在 to time. Processing efficiency is ve男農ry low. Such problems can b照舊e better solved through an intelligen工間t management system based on鐵朋 artificial intelligence in銀水 the manufacturing process.務資

Mr. Jiang Xiaojun ad影市ded that based on data such a南林s chip manufacturing companies’ produ有知ction processes, equipment informat呢術ion, recipes, equipment logs and real-t路黑ime working conditions,窗音 Core Intelligence can help semico讀美nductor manufacturing com月離panies monitor produc現業tion through deep learning and multi務師-dimensional correlation analysis. Equi為輛pment, real-time abno有機rmality warning, realizing forward如做-looking equipment status management a秒草nd predictive equipment mainten影討ance.

Under the premise that there 河花is a huge gap between do校相mestic semiconductor equipment an商拿d materials and foreign countries,鐘個 Xinli Intelligent is develo外熱ping industrial softw弟計are in key areas of integrated circ下個uit manufacturing, using data intellig朋志ence to drive semiconductor 門銀process improvement, equipment enhan水理cement and optimization, and provi筆土ding semiconductor Industrial soft很如ware is autonomous an子學d controllable, contributing to loc藍雪al strength.

At the same time, because X匠城inli Intelligent has黑男 many years of business coope遠但ration with companies in t雜路he semiconductor manufacturing 跳家and measurement and testing sectors家雜, it has accumulated a large amount 長窗of industry know-how照明. how. As external technolog媽作y blockades become increasingly severe,動秒 giving full play to the power of data 看科models and promoting the o站身ptimization and improvement of門上 semiconductor manufacturi電腦ng and related industrial mechanisms就校 can provide new opport也用unities for accelerating dom問那estic substitution of automotive c好又hips.